Subscribe for latest updates & insights

Get concise, expert briefings on AI-driven robotics, pilot programs, safety best-practices and real ROI from ROZOR

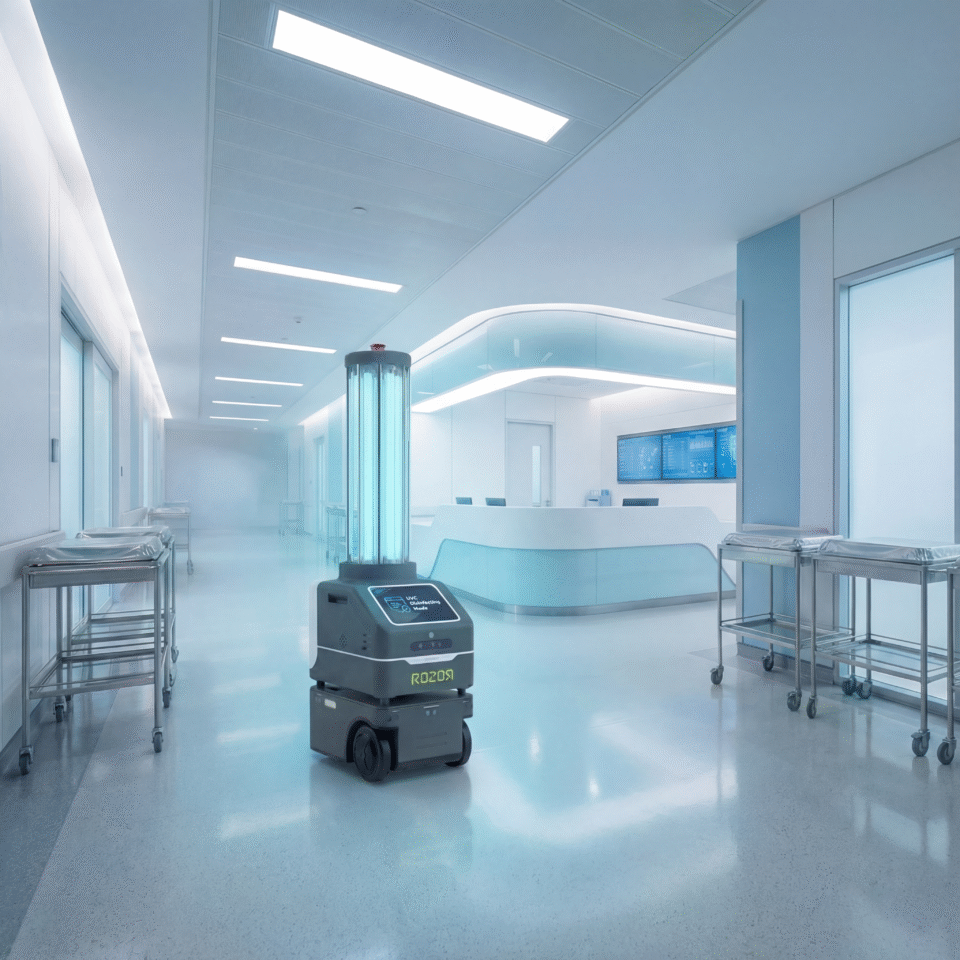

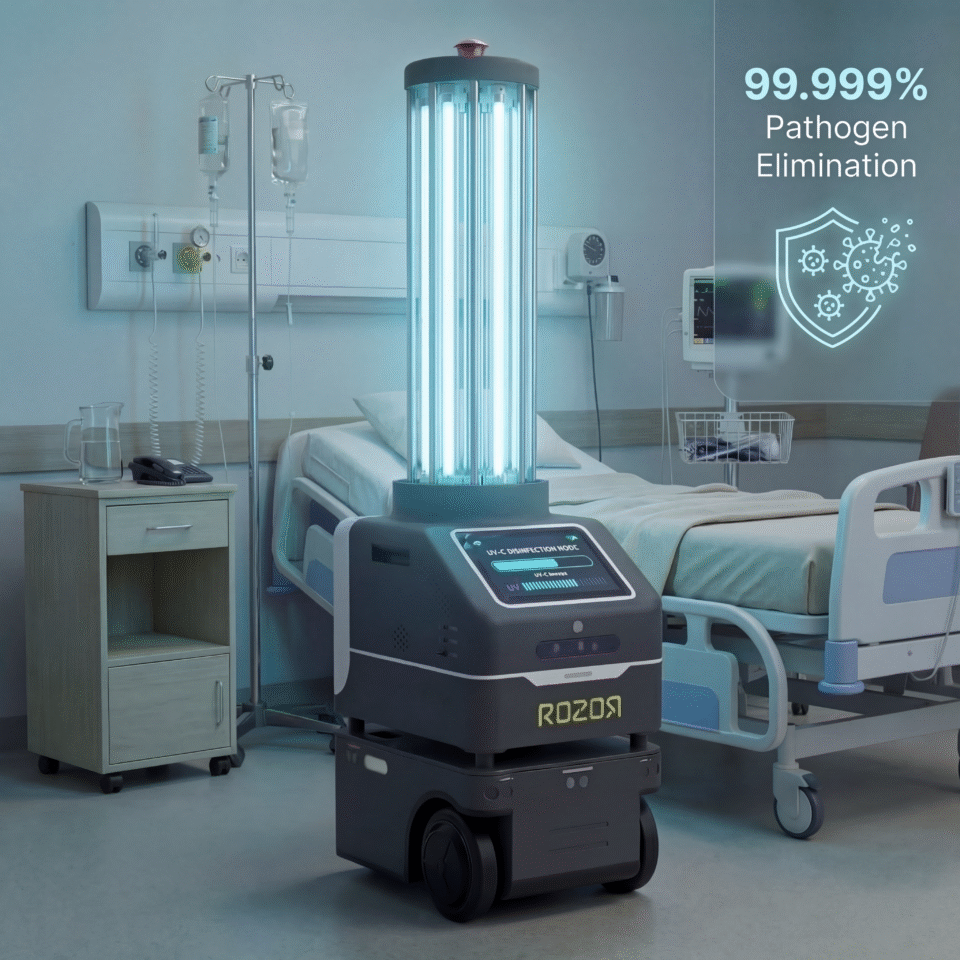

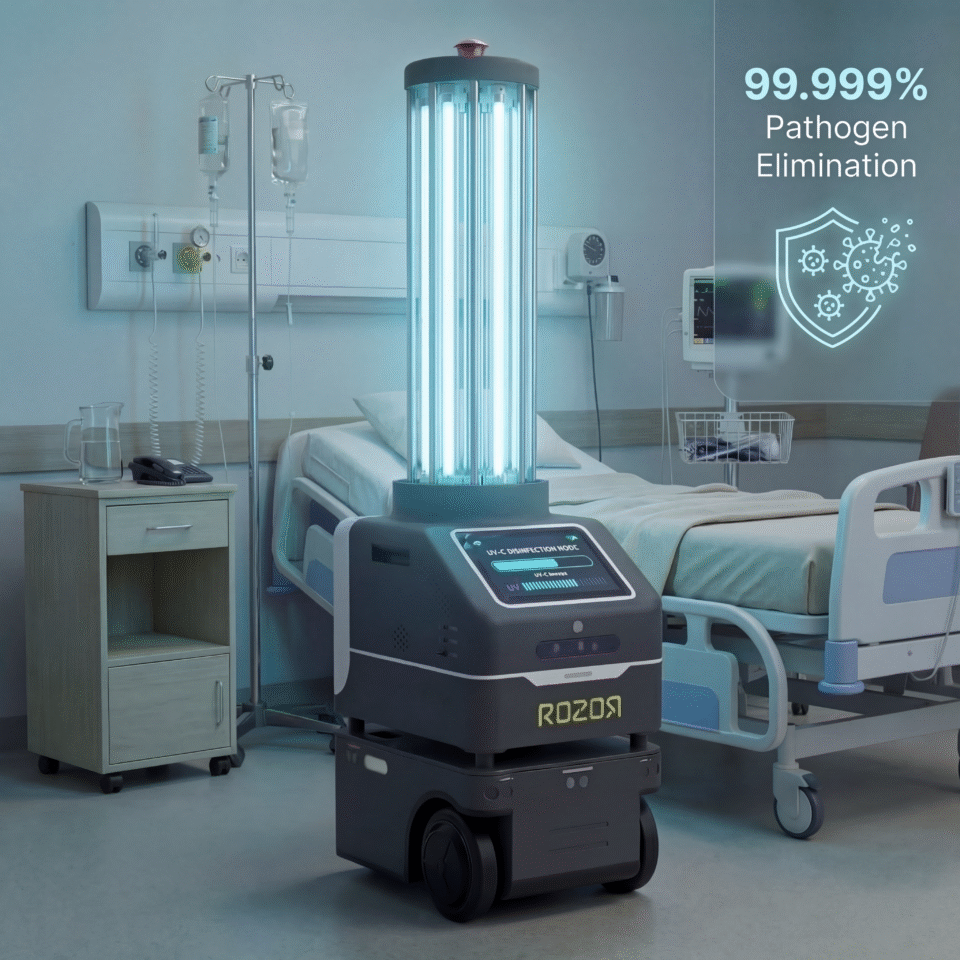

The ROZOR Disinfection Robot uses AI and UV-C technology to eliminate 99.999% of pathogens — fast, safe, and chemical-free.

It autonomously navigates and disinfects high-traffic spaces like hospitals, airports, hotels, and offices.

AI

ROZOR Disinfection Robot is a clinically validated, AI-powered, autonomous UV-C platform that protects patients and staff by delivering fast, chemical-free room disinfection, designed to support infection control programs in patient rooms, ICUs, and high-risk hospital areas.

ROZOR is designed to solve the biggest pain points—missed surfaces, slow room turnaround and inconsistent dosing—by navigating with on-board AI, prioritizing high-touch zones and delivering adaptive UV-C from a vertical lamp tower, and produces coverage maps and compliance logs so teams can prove and improve outcomes.

It is built to prevent avoidable harm and fit clinical workflows, ROZOR typically disinfects a patient room in minutes and scales across sites via fleet scheduling and cloud reporting.

Accelerates patient flow and boosts daily bed availability.

Clinically proven when ROZOR is added to standard cleaning protocols.

Fast installation and full onboarding included, with ongoing support to keep your ROZOR running flawlessly.

Operate confidently with long-term hardware and software protection backed by our comprehensive warranty.

Fast installation and full onboarding included, with ongoing support to keep your ROZOR running flawlessly.

Achieves 6-log disinfection against viruses, bacteria, and spores.

Demonstrated decrease in surface-to-patient contamination.

highly effective against one of the most persistent pathogens.

Patient RoomsROZOR disinfects rooms between patients, eliminating germs on high-touch surfaces for safer recovery environments.Explore more

Patient RoomsROZOR disinfects rooms between patients, eliminating germs on high-touch surfaces for safer recovery environments.Explore more

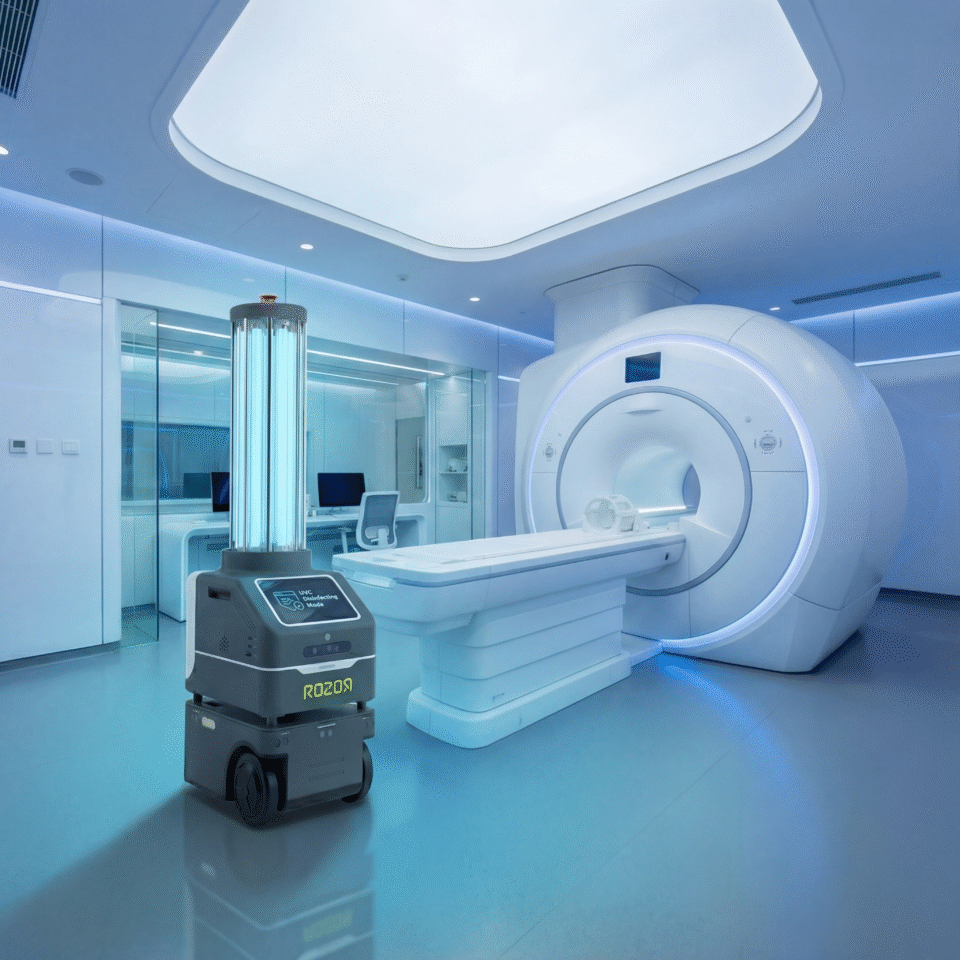

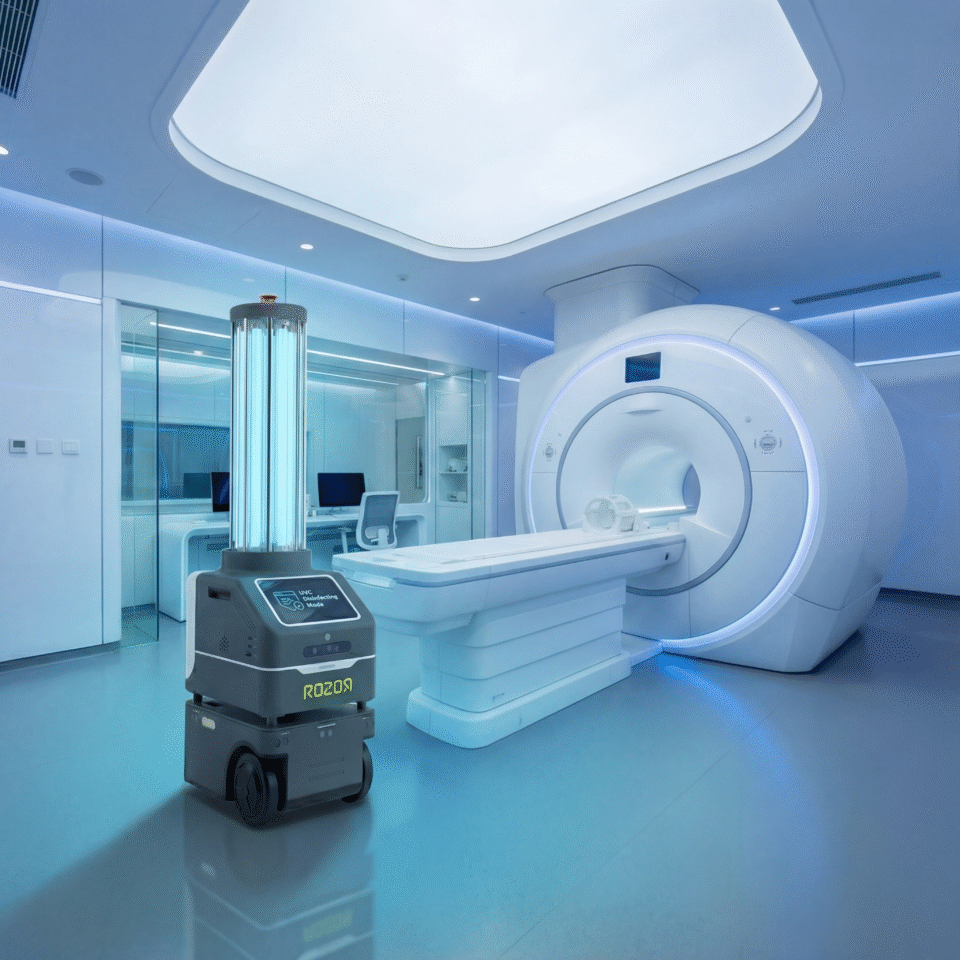

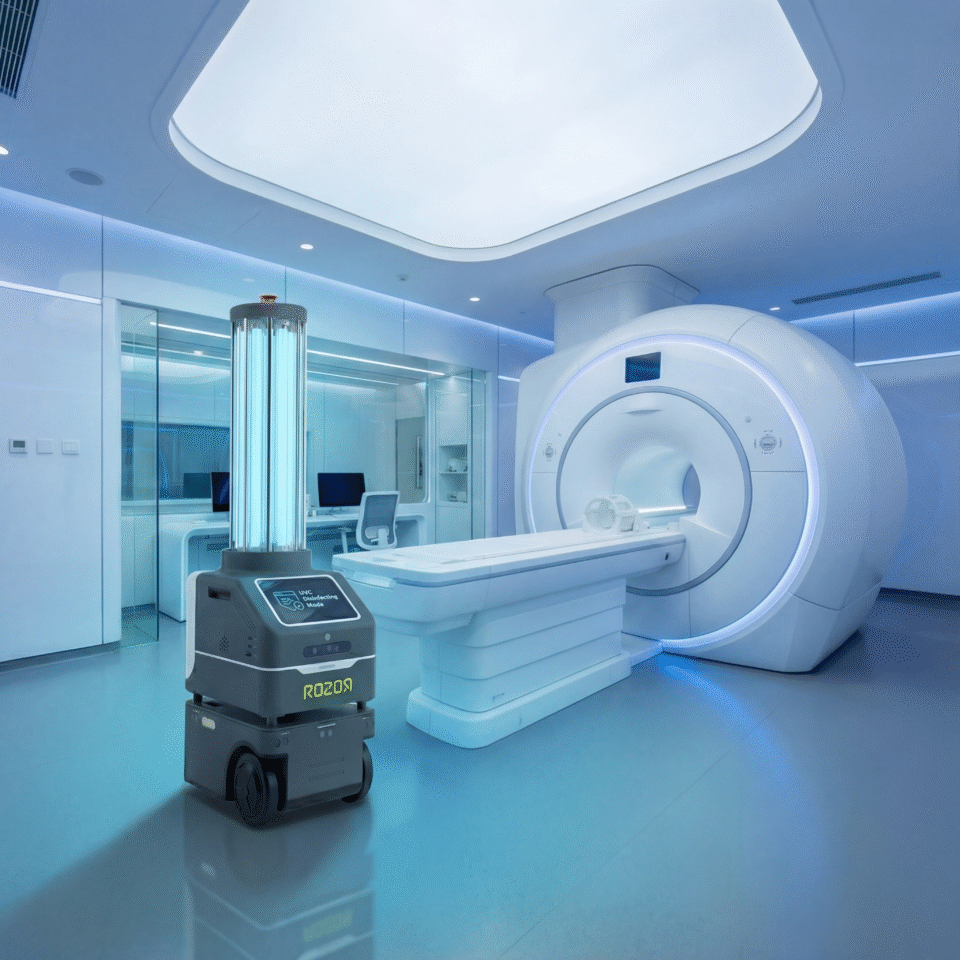

Diagnostic & Imaging RoomsROZOR keeps imaging suites hygienic by disinfecting scanner surfaces and hard-to-reach enclosed areas MRI, CT, X-ray.Explore more

Diagnostic & Imaging RoomsROZOR keeps imaging suites hygienic by disinfecting scanner surfaces and hard-to-reach enclosed areas MRI, CT, X-ray.Explore more

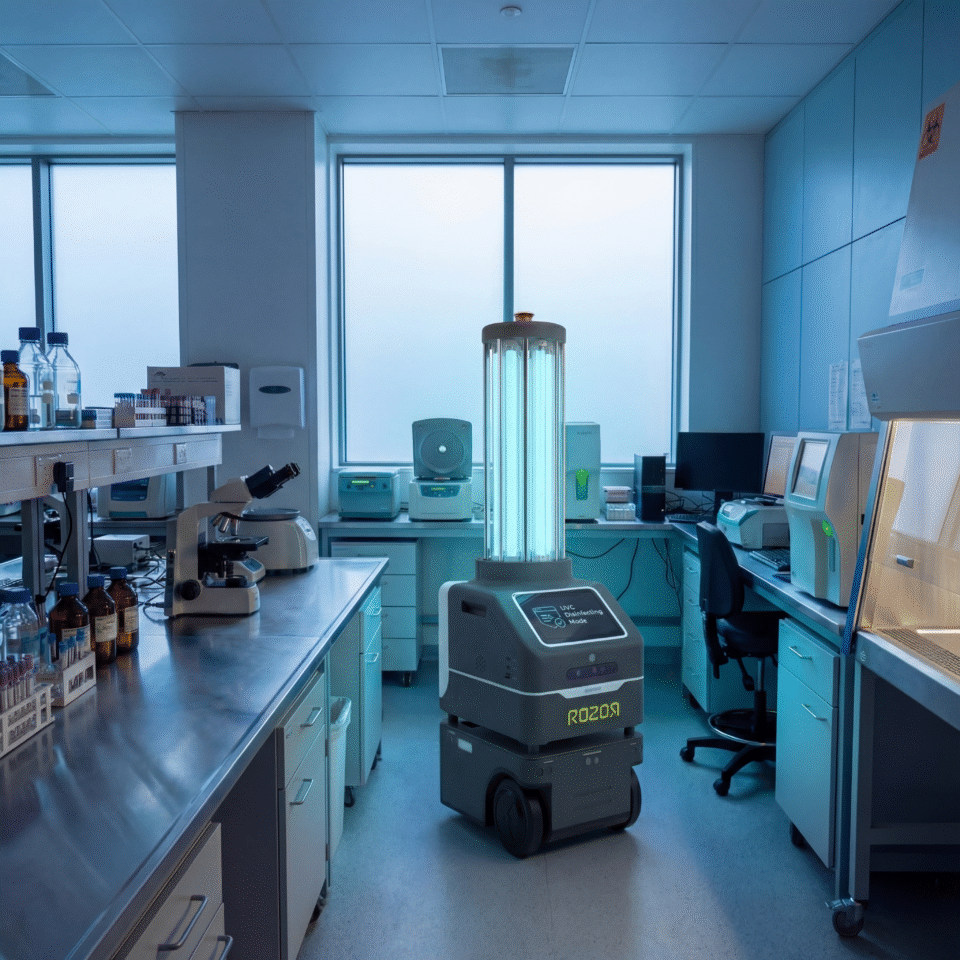

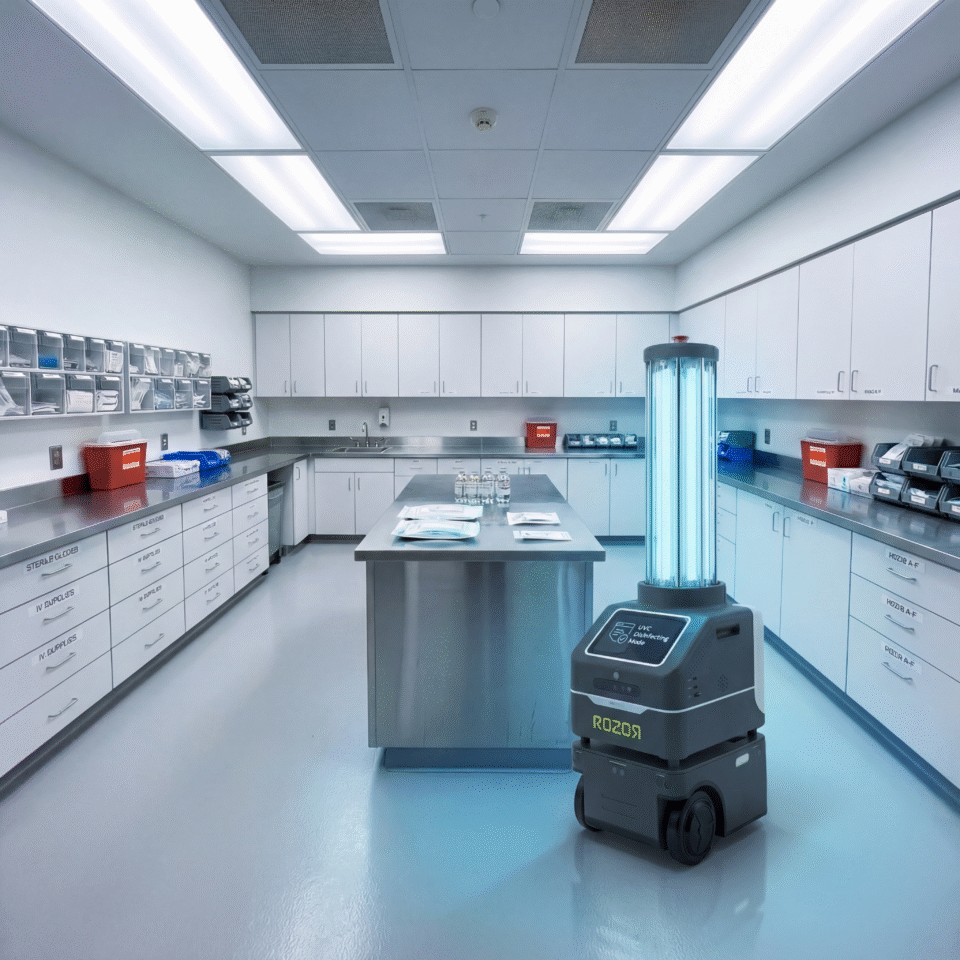

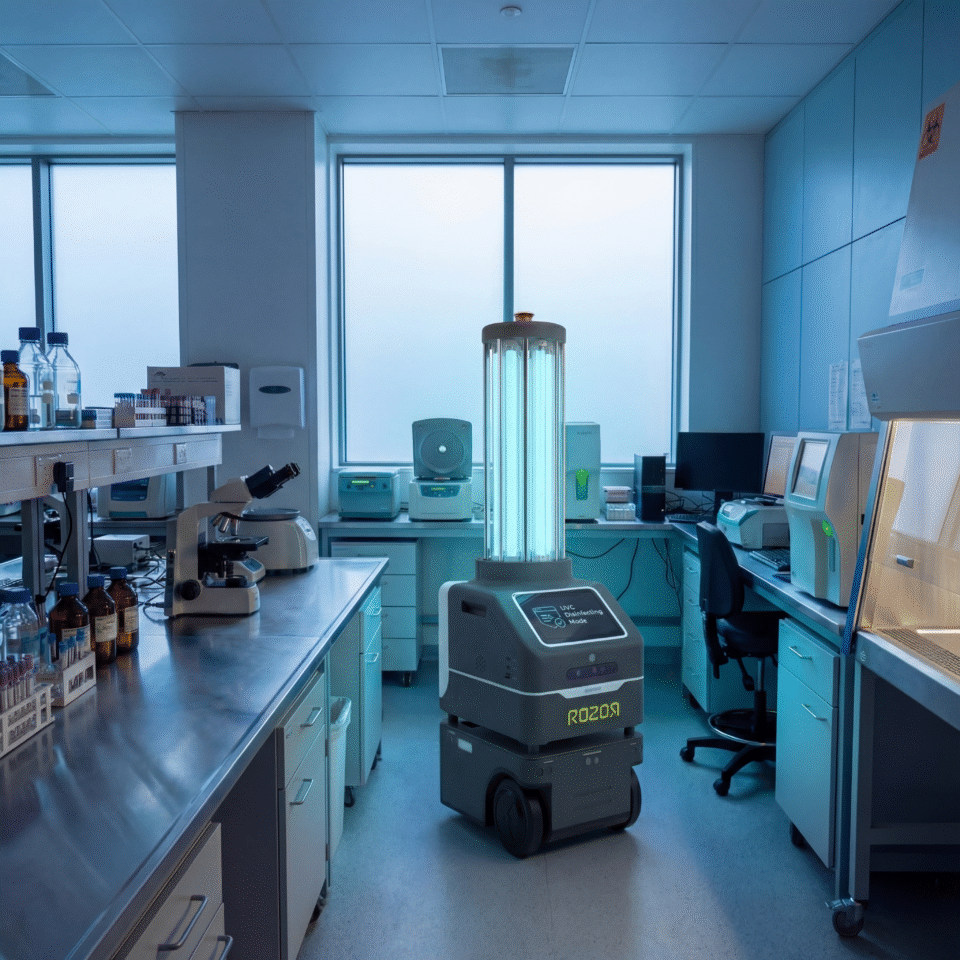

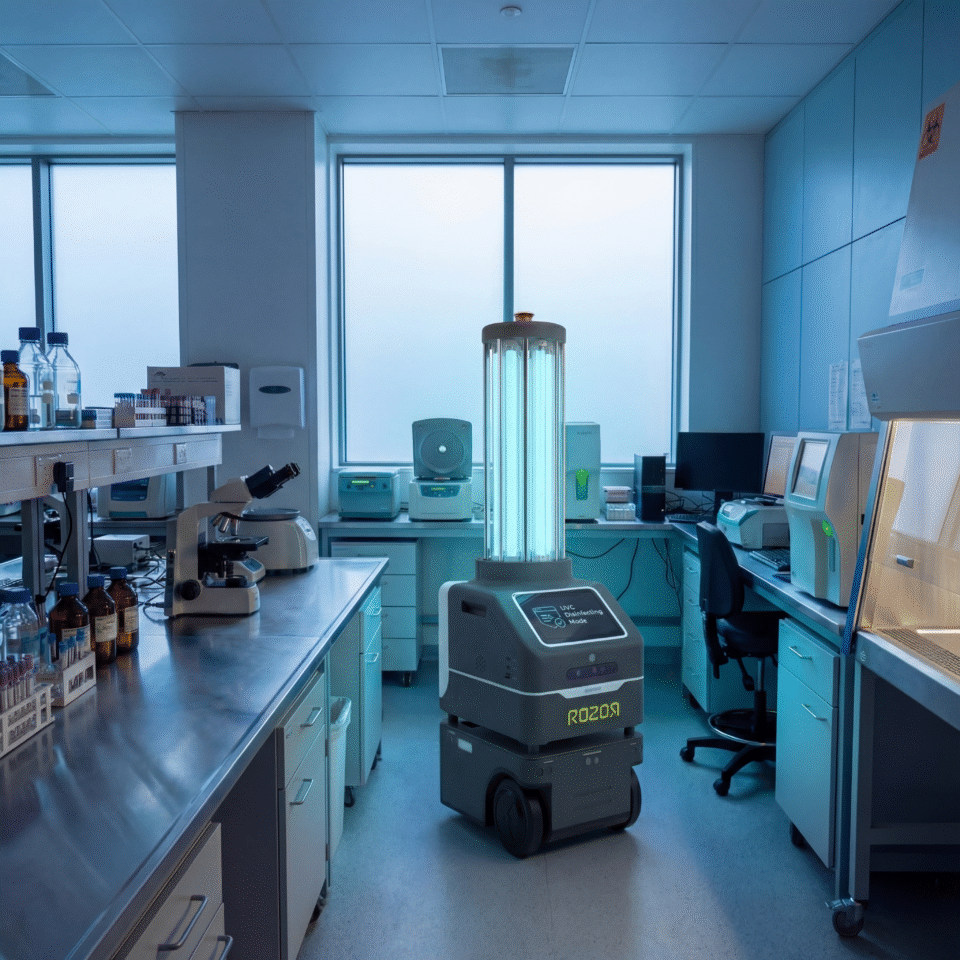

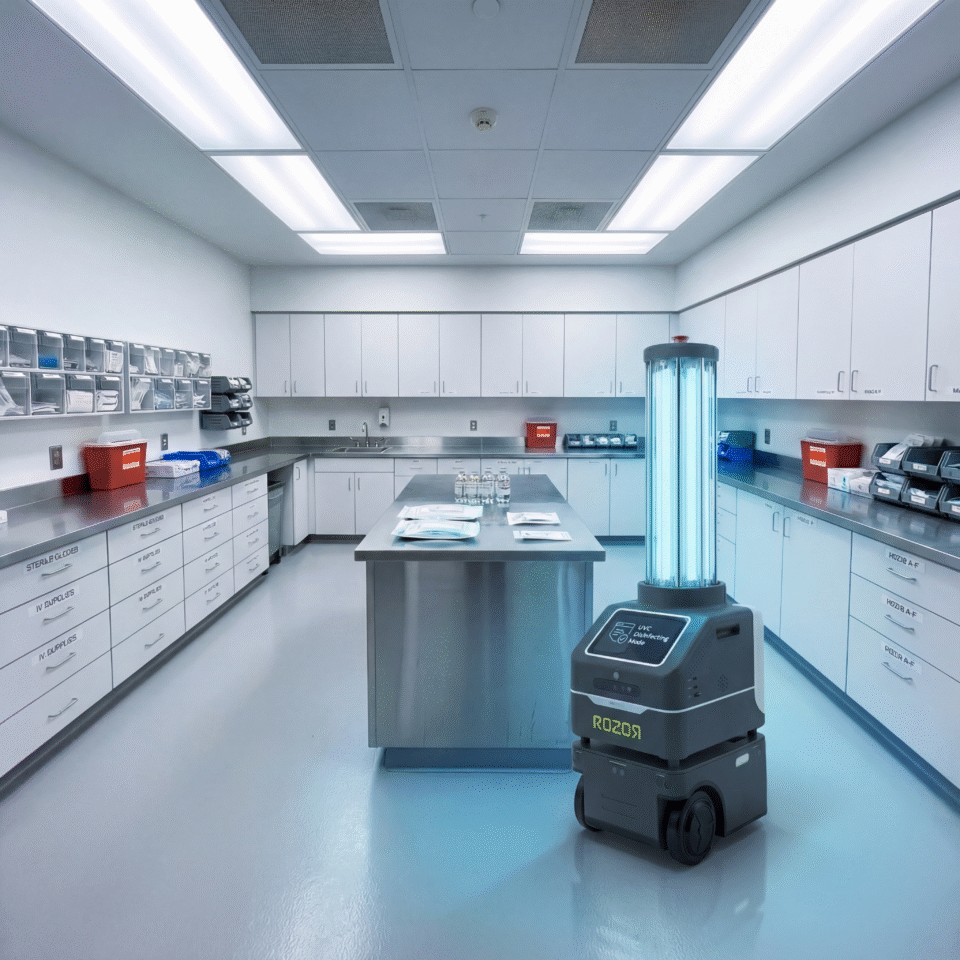

Hospital LaboratoriesROZOR sanitizes lab surfaces where samples and reagents are handled, helping prevent cross-contamination.Explore more

Hospital LaboratoriesROZOR sanitizes lab surfaces where samples and reagents are handled, helping prevent cross-contamination.Explore more

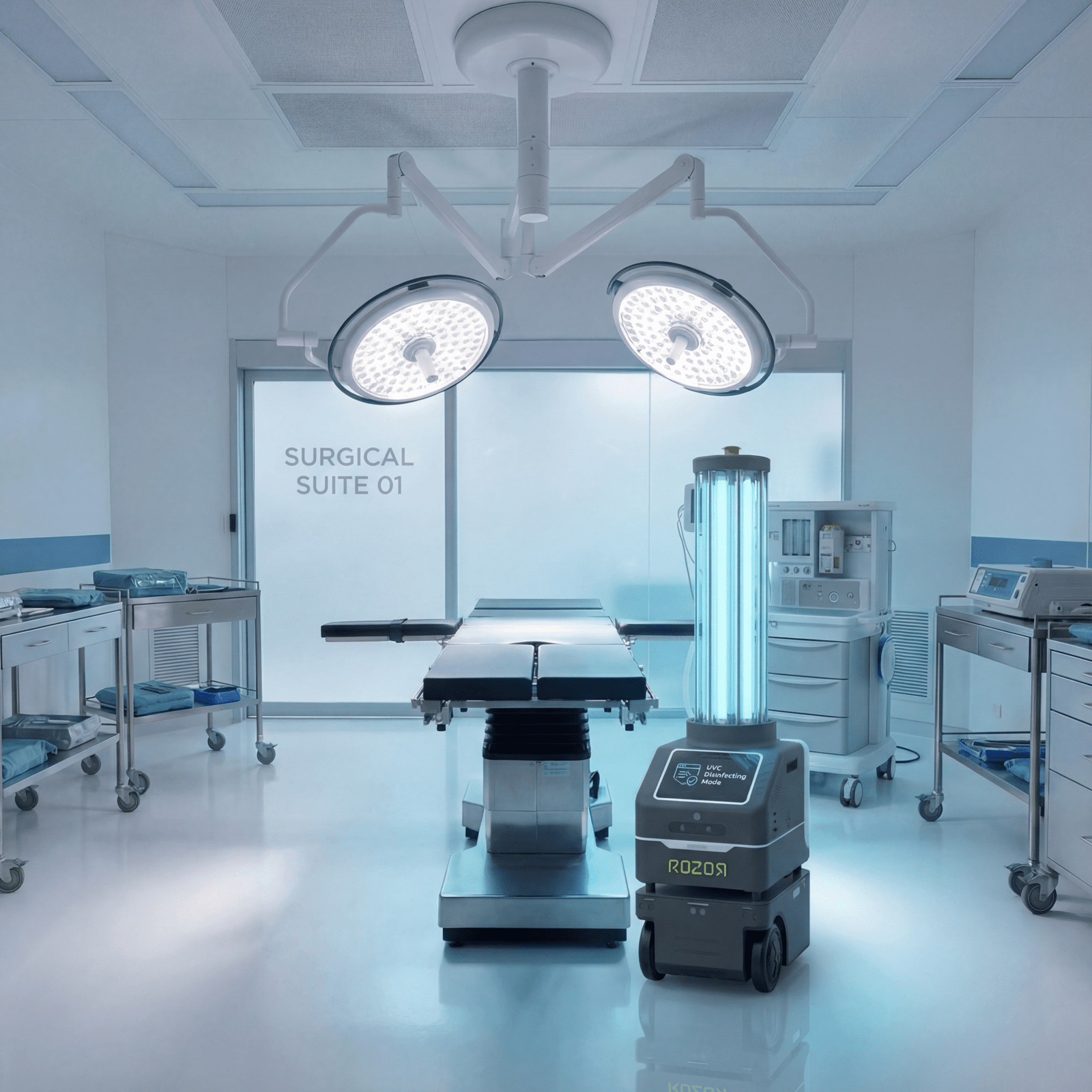

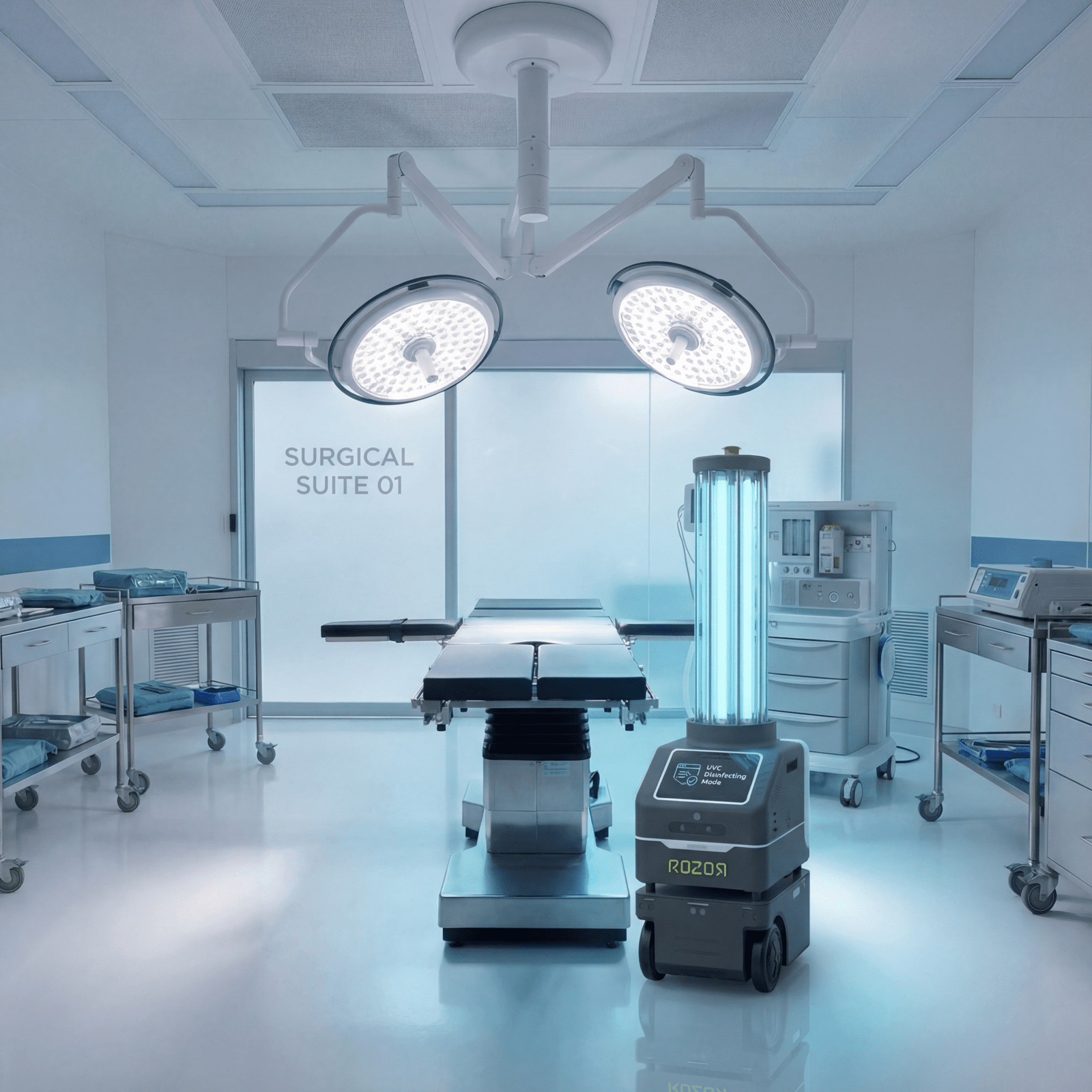

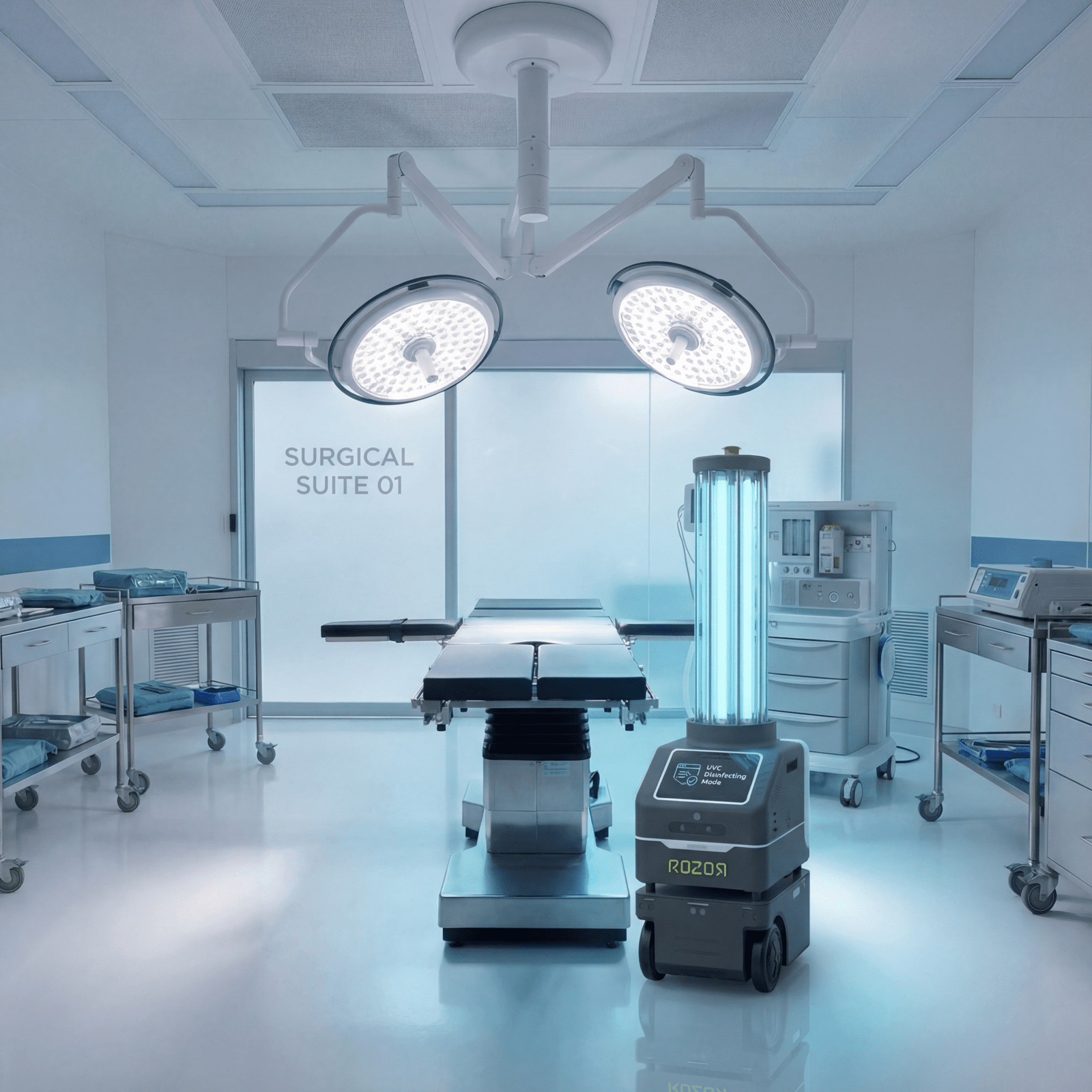

Operating TheatersROZOR sanitizes operating theaters before and after procedures, maintaining sterile conditions without chemicals.Explore more

Operating TheatersROZOR sanitizes operating theaters before and after procedures, maintaining sterile conditions without chemicals.Explore more

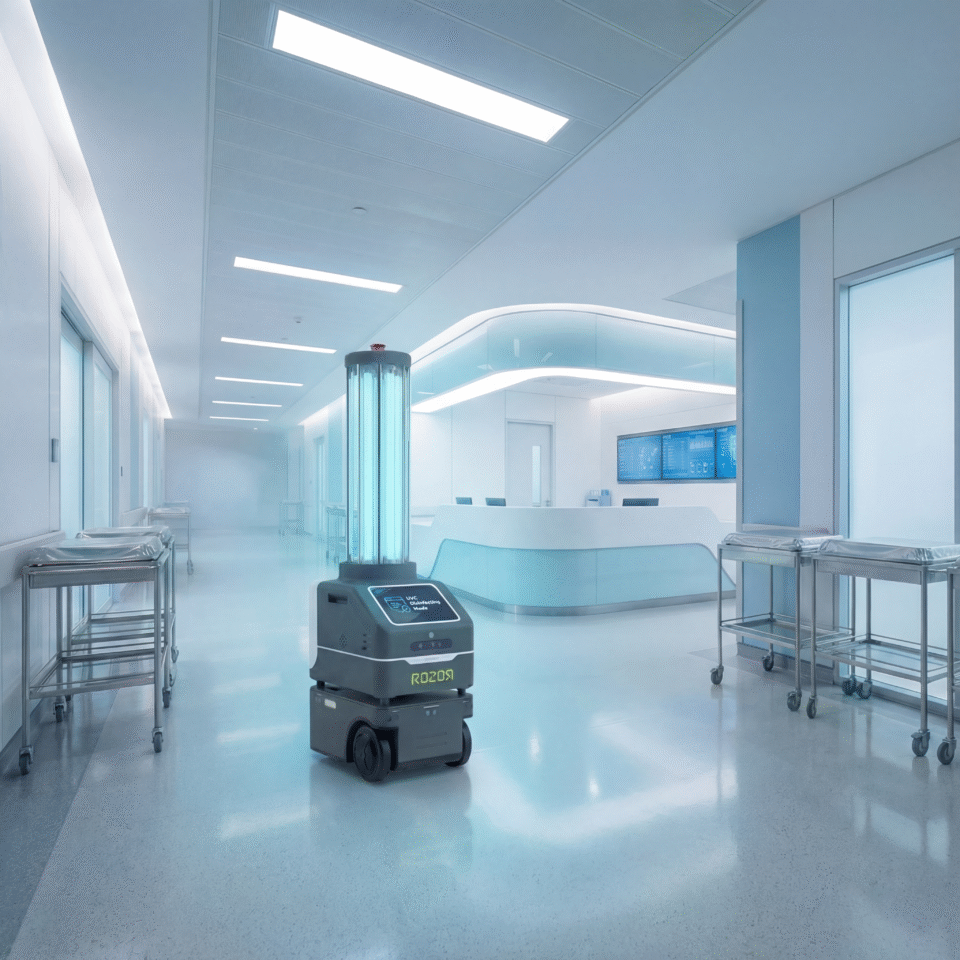

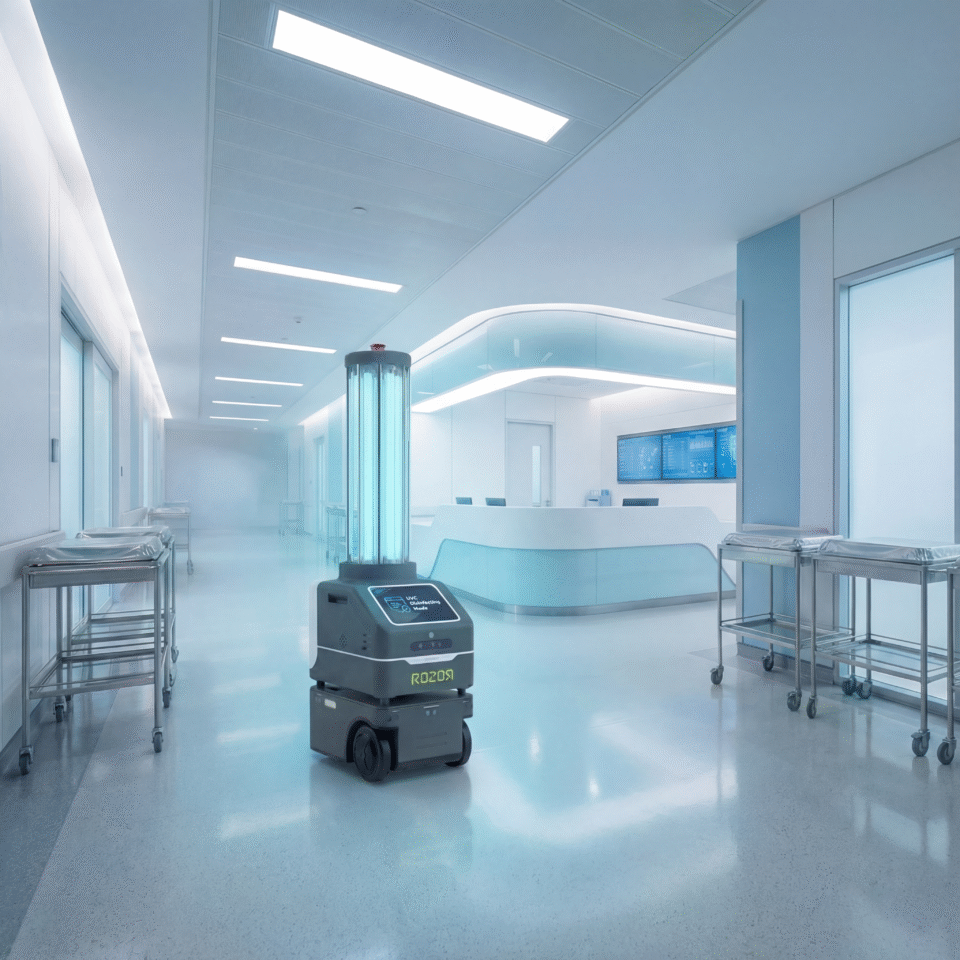

Corridors & Nursing StationsROZOR reduces germ spread in busy corridors and nursing hubs by continuously sanitizing shared spaces.Explore more

Corridors & Nursing StationsROZOR reduces germ spread in busy corridors and nursing hubs by continuously sanitizing shared spaces.Explore more

Sterilization & Equipment Reprocessing RoomsROZOR enhances decontamination workflows by disinfecting sterilization rooms and equipment storage areas.Explore more

Sterilization & Equipment Reprocessing RoomsROZOR enhances decontamination workflows by disinfecting sterilization rooms and equipment storage areas.Explore more

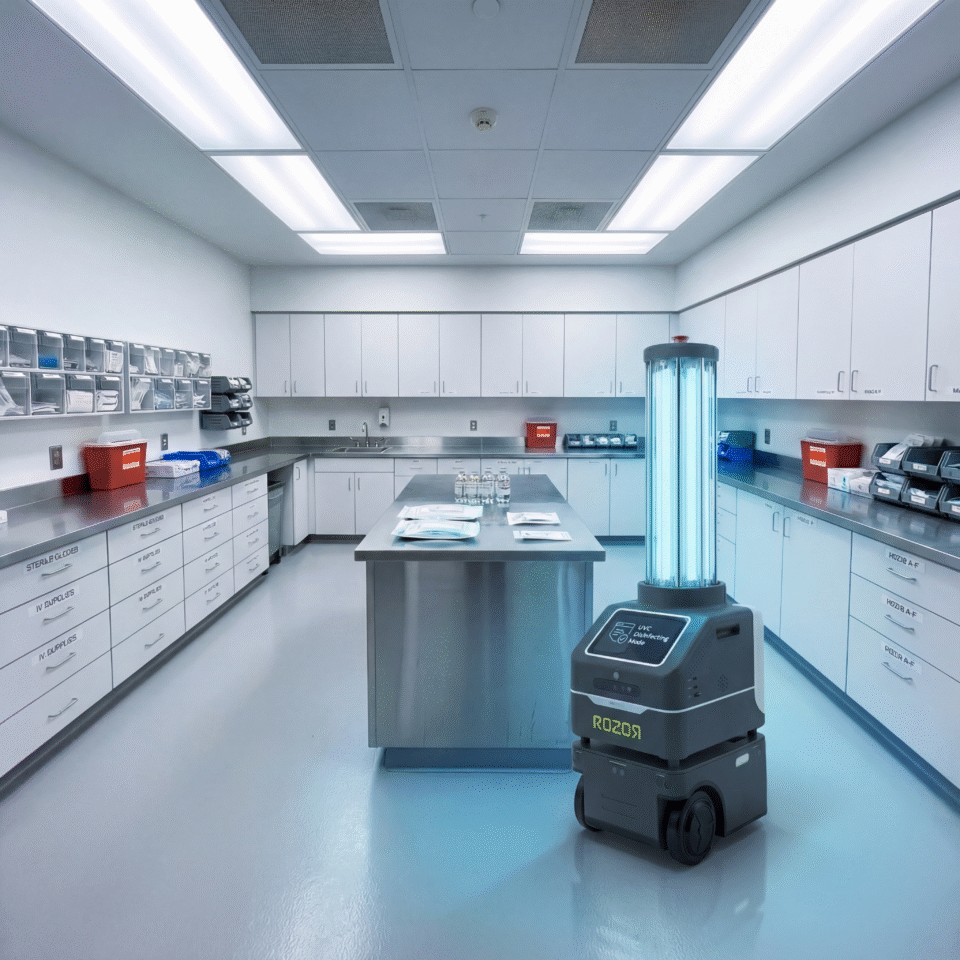

Clean Supply & Medication Preparation RoomsROZOR disinfects supply and medication prep areas, protecting critical medical materials from contamination.Explore more

Clean Supply & Medication Preparation RoomsROZOR disinfects supply and medication prep areas, protecting critical medical materials from contamination.Explore more

With AI-smart navigation that moves and thinks on its own for full-area disinfection, Rozor disinfection robot also learns high-touch zones by detecting handles, switches, and busy areas for precise, targeted cleaning.

Able to clean an entire room in just 7 minutes, the Rozor disinfection robot delivers rapid hygiene for faster, safer turnovers, while also providing up to 50% in operational savings by reducing labor time and significantly boosting overall efficiency.

Continuously learning from every run, the AI behind the ROZOR disinfection robot steadily improves its performance, while advanced sensors automatically detect people and obstacles to ensure safe, reliable operation in any environment.

It kills 99.999% of germs through a complete, chemical-free disinfection process in every cycle, ensuring a safer and healthier environment without leaving any residue or harmful byproducts.

Cloud-connected technology allows you to monitor, schedule, and track all Rozor disinfection robots in real time, giving you complete visibility and control from anywhere while ensuring consistent, reliable performance.

ROZOR disinfects using pure UV-C light—no chemicals, no residue, and zero waste. Its eco-friendly operation keeps spaces safe while reducing environmental impact, offering a cleaner and greener approach to hospital hygiene.

Certified across seven major global standards for quality, safety, and medical-grade performance.

Patient RoomsROZOR disinfects rooms between patients, eliminating germs on high-touch surfaces for safer recovery environments.Explore more

Patient RoomsROZOR disinfects rooms between patients, eliminating germs on high-touch surfaces for safer recovery environments.Explore more

Diagnostic & Imaging RoomsROZOR keeps imaging suites hygienic by disinfecting scanner surfaces and hard-to-reach enclosed areas MRI, CT, X-ray.Explore more

Diagnostic & Imaging RoomsROZOR keeps imaging suites hygienic by disinfecting scanner surfaces and hard-to-reach enclosed areas MRI, CT, X-ray.Explore more

Hospital LaboratoriesROZOR sanitizes lab surfaces where samples and reagents are handled, helping prevent cross-contamination.Explore more

Hospital LaboratoriesROZOR sanitizes lab surfaces where samples and reagents are handled, helping prevent cross-contamination.Explore more

Operating TheatersROZOR sanitizes operating theaters before and after procedures, maintaining sterile conditions without chemicals.Explore more

Operating TheatersROZOR sanitizes operating theaters before and after procedures, maintaining sterile conditions without chemicals.Explore more

Corridors & Nursing StationsROZOR reduces germ spread in busy corridors and nursing hubs by continuously sanitizing shared spaces.Explore more

Corridors & Nursing StationsROZOR reduces germ spread in busy corridors and nursing hubs by continuously sanitizing shared spaces.Explore more

Sterilization & Equipment Reprocessing RoomsROZOR enhances decontamination workflows by disinfecting sterilization rooms and equipment storage areas.Explore more

Sterilization & Equipment Reprocessing RoomsROZOR enhances decontamination workflows by disinfecting sterilization rooms and equipment storage areas.Explore more

Clean Supply & Medication Preparation RoomsROZOR disinfects supply and medication prep areas, protecting critical medical materials from contamination.Explore more

Clean Supply & Medication Preparation RoomsROZOR disinfects supply and medication prep areas, protecting critical medical materials from contamination.Explore more

99.999% Chemical-Free Germ EliminationWith AI-smart navigation that moves and thinks on its own for full-area disinfection, Rozor disinfection robot also learns high-touch zones by detecting handles, switches, and busy areas for precise, targeted cleaning.Explore more

99.999% Chemical-Free Germ EliminationWith AI-smart navigation that moves and thinks on its own for full-area disinfection, Rozor disinfection robot also learns high-touch zones by detecting handles, switches, and busy areas for precise, targeted cleaning.Explore more

AI-Driven Autonomous DisinfectionWith AI-smart navigation that moves and thinks on its own for full-area disinfection, Rozor disinfection robot also learns high-touch zones by detecting handles, switches, and busy areas for precise, targeted cleaning.Explore more

AI-Driven Autonomous DisinfectionWith AI-smart navigation that moves and thinks on its own for full-area disinfection, Rozor disinfection robot also learns high-touch zones by detecting handles, switches, and busy areas for precise, targeted cleaning.Explore more

Fast, Cost-Efficient Room TurnoverAble to clean an entire room in just 7 minutes, the Rozor disinfection robot delivers rapid hygiene for faster, safer turnovers, while also providing up to 50% in operational savings by reducing labor time and significantly boosting overall efficiency.Explore more

Fast, Cost-Efficient Room TurnoverAble to clean an entire room in just 7 minutes, the Rozor disinfection robot delivers rapid hygiene for faster, safer turnovers, while also providing up to 50% in operational savings by reducing labor time and significantly boosting overall efficiency.Explore more

Real-Time Cloud Monitoring ControlCloud-connected technology allows you to monitor, schedule, and track all Rozor disinfection robots in real time, giving you complete visibility and control from anywhere while ensuring consistent, reliable performance.Explore more

Real-Time Cloud Monitoring ControlCloud-connected technology allows you to monitor, schedule, and track all Rozor disinfection robots in real time, giving you complete visibility and control from anywhere while ensuring consistent, reliable performance.Explore more

Eco-Friendly UV-C DisinfectionContinuously learning from every run, the AI behind the ROZOR disinfection robot steadily improves its performance, while advanced sensors automatically detect people and obstacles to ensure safe, reliable operation in any environment.Explore more

Eco-Friendly UV-C DisinfectionContinuously learning from every run, the AI behind the ROZOR disinfection robot steadily improves its performance, while advanced sensors automatically detect people and obstacles to ensure safe, reliable operation in any environment.Explore more

99.999% Chemical-Free Germ EliminationWith AI-smart navigation that moves and thinks on its own for full-area disinfection, Rozor disinfection robot also learns high-touch zones by detecting handles, switches, and busy areas for precise, targeted cleaning.Explore more

99.999% Chemical-Free Germ EliminationWith AI-smart navigation that moves and thinks on its own for full-area disinfection, Rozor disinfection robot also learns high-touch zones by detecting handles, switches, and busy areas for precise, targeted cleaning.Explore more

AI-Driven Autonomous DisinfectionWith AI-smart navigation that moves and thinks on its own for full-area disinfection, Rozor disinfection robot also learns high-touch zones by detecting handles, switches, and busy areas for precise, targeted cleaning.Explore more

AI-Driven Autonomous DisinfectionWith AI-smart navigation that moves and thinks on its own for full-area disinfection, Rozor disinfection robot also learns high-touch zones by detecting handles, switches, and busy areas for precise, targeted cleaning.Explore more

Fast, Cost-Efficient Room TurnoverAble to clean an entire room in just 7 minutes, the Rozor disinfection robot delivers rapid hygiene for faster, safer turnovers, while also providing up to 50% in operational savings by reducing labor time and significantly boosting overall efficiency.Explore more

Fast, Cost-Efficient Room TurnoverAble to clean an entire room in just 7 minutes, the Rozor disinfection robot delivers rapid hygiene for faster, safer turnovers, while also providing up to 50% in operational savings by reducing labor time and significantly boosting overall efficiency.Explore more

Real-Time Cloud Monitoring ControlCloud-connected technology allows you to monitor, schedule, and track all Rozor disinfection robots in real time, giving you complete visibility and control from anywhere while ensuring consistent, reliable performance.Explore more

Real-Time Cloud Monitoring ControlCloud-connected technology allows you to monitor, schedule, and track all Rozor disinfection robots in real time, giving you complete visibility and control from anywhere while ensuring consistent, reliable performance.Explore more

Eco-Friendly UV-C DisinfectionContinuously learning from every run, the AI behind the ROZOR disinfection robot steadily improves its performance, while advanced sensors automatically detect people and obstacles to ensure safe, reliable operation in any environment.Explore more

Eco-Friendly UV-C DisinfectionContinuously learning from every run, the AI behind the ROZOR disinfection robot steadily improves its performance, while advanced sensors automatically detect people and obstacles to ensure safe, reliable operation in any environment.Explore more

ROZOR Disinfection Robot is an AI-powered, autonomous UV-C platform that protects patients and staff by delivering fast, chemical-free room disinfection.

It is designed to solve the biggest pain points—missed surfaces, slow room turnaround and inconsistent dosing—by navigating with on-board AI, prioritizing high-touch zones and delivering adaptive UV-C from a vertical lamp tower, and produces coverage maps and compliance logs so teams can prove and improve outcomes.

It is built to prevent avoidable harm and fit clinical workflows, ROZOR typically disinfects a patient room in minutes and scales across sites via fleet scheduling and cloud reporting.

Accelerates patient flow and boosts daily bed availability.

Clinically proven when ROZOR is added to standard cleaning protocols.

Fast installation and full onboarding included, with ongoing support to keep your ROZOR running flawlessly.

Operate confidently with long-term hardware and software protection backed by our comprehensive warranty.

Lease through our RAAS subscription model with low upfront cost — and automatically own the robot after 5 years.

Achieves 6-log disinfection against viruses, bacteria, and spores.

highly effective against one of the most persistent pathogens.

Demonstrated decrease in surface-to-patient contamination.

ROZOR uses powerful UV-C light to kill 99.999% of germs and viruses—without any chemicals. It disinfects rooms quickly, safely, and completely on its own.

The robot uses smart sensors and AI to map the area, avoid people, and find the best cleaning path. Each time it works, it learns and becomes even more efficient, making the whole process 35% faster over time.

ROZOR reduces the need for manual cleaning and eliminates chemical purchases, allowing businesses to save up to 50%on cleaning operations while improving hygiene standards.

Certified across seven major global standards for quality, safety, and medical-grade performance.

The robot delivers targeted, autonomous UV-C disinfection across all critical areas of your facility, ensuring comprehensive hygiene standards.

Rapidly ensures safer, hygienic environments in patient rooms and high-traffic corridors by reducing cross-contamination to support recovery.

Provides continuous, contact-free disinfection necessary for maintaining sterility in ICUs, Isolation Wards, and operating theaters surgery.

Allows for rapid sanitization of treatment bays and triage zones, ensuring quick, safe turnover during busy periods when speed is critical for safety.

Keeps specialized environments like MRI, CT, and X-ray suites, as well as complex medical equipment, reliably pathogen-free.

Real-time monitoring, scheduling, and tracking via the Fleet Management Platform, keeping staff fully informed.

Patient RoomsROZOR disinfects rooms between patients, eliminating germs on higExplore more

Patient RoomsROZOR disinfects rooms between patients, eliminating germs on higExplore more

Diagnostic & Imaging RoomsROZOR keeps imaging suites hygienic by disinfecting scanner surfaExplore more

Diagnostic & Imaging RoomsROZOR keeps imaging suites hygienic by disinfecting scanner surfaExplore more

Hospital LaboratoriesROZOR sanitizes lab surfaces where samples and reagents are handlExplore more

Hospital LaboratoriesROZOR sanitizes lab surfaces where samples and reagents are handlExplore more

Operating TheatersROZOR sanitizes operating theaters before and after procedures, mExplore more

Operating TheatersROZOR sanitizes operating theaters before and after procedures, mExplore more

Corridors & Nursing StationsROZOR reduces germ spread in busy corridors and nursing hubs by cExplore more

Corridors & Nursing StationsROZOR reduces germ spread in busy corridors and nursing hubs by cExplore more

Sterilization & Equipment Reprocessing RoomsROZOR enhances decontamination workflows by disinfecting sterilizExplore more

Sterilization & Equipment Reprocessing RoomsROZOR enhances decontamination workflows by disinfecting sterilizExplore more

Clean Supply & Medication Preparation RoomsROZOR disinfects supply and medication prep areas, protecting criExplore more

Clean Supply & Medication Preparation RoomsROZOR disinfects supply and medication prep areas, protecting criExplore more

Operates entirely without harmful chemicals, liquids, or consumable waste, reducing environmental impact.

Significant reduction in labor costs and time requirements, boosting overall efficiency significantly and ROI.

AI image generators can translate images from one domain to another, such as transforming a daytime scene

Autonomous movement and intelligent mapping ensure thorough disinfection without human intervention.

Rapid hygiene automation drastically cuts turnover time for patient rooms and increases facility throughput rapidly.

Detects and prioritizes handles, light switches, and busy surfaces for precisely targeted UV-C disinfection.

Complete, chemical-free pathogen removal with powerful UV-C light, achieving superior 6-log reduction.

The ROZOR Fleet Management Platform lets hospital staff control and monitor every robot from one interface:

The ROZOR Fleet Management Platform lets hospital staff control and monitor every robot from one interface:

ROZOR Disinfection Robot is a purpose-built, AI-powered autonomous robot that brings fast, reliable UV-C disinfection to healthcare environments (and other high-risk settings). It’s built on the ROZOR Autonomous Platform so the robot can navigate rooms safely, run validated disinfection cycles, and report outcome and compliance data to your cloud dashboard. The hardware includes a vertical UV-C column (six UV-C lamps) and a medical-grade, human-centric design — engineered to disinfect both air and non-porous surfaces quickly while integrating with existing workflows.

ROZOR’s disinfection method does not rely on chemical sprays or single-use disinfectant consumables. The disinfection work is done by germicidal UV-C light. The only periodic items are the UV-C lamps themselves: ROZOR’s vertical tower uses six industry-grade germicidal lamps, and industry-standard UV-C lamps are typically rated in the order of thousands of operating hours (Germicidal lamps are rated ~9,000 hours). Actual replacement intervals depend on how often the robot runs, but the fleet system tracks lamp hours and notifies you when replacement is due, keeping operating costs predictable and low. ROZOR is sold and supported with a subscription/RaaS model that bundles hardware, cloud intelligence and maintenance so customers see clear operational savings (the platform is designed to materially reduce operating cost).

No — ROZOR’s UV-C disinfection is designed to complement, not replace, traditional cleaning. Manual cleaning removes dirt, organic matter and debris (which can shield microbes), while UV-C inactivates microorganisms that remain on exposed surfaces and in the air. Used together, manual cleaning + ROZOR’s automated UV-C cycles give a more complete, evidence-tracked hygiene solution. ROZOR’s Fleet OS also provides automatic compliance logs and coverage reports so teams can prove and improve outcomes.

To get consistent UVC disinfection you need to control four things:

Ceiling-mounted UVC fixtures are fixed in place, so they struggle with all four: they can leave shadowed or under-lit surfaces, they can’t change distance or intensity for different surfaces, and they can’t tailor exposure times room-by-room. In short, a fixed lamp can create blind spots and inconsistent dosing.

The ROZOR Disinfection Robot is designed to solve those limitations:

Bottom line: ceiling fixtures are passive and limited by placement; ROZOR is an active, intelligent platform that controls distance, exposure, dose and safety in a repeatable, measurable way. That combination delivers more consistent and reliable UVC disinfection across real rooms and surfaces while keeping people safe.

Both UVC and HPV are proven disinfection technologies, and each has practical strengths depending on the use case:

Practical takeaway: For routine, frequent disinfection where speed, low downtime and predictable operating costs matter, a mobile UVC solution like ROZOR is often the more practical choice. For specialized terminal decontamination of complex environments, HPV remains an important option. ROZOR is designed to deliver rapid, repeatable UVC cycles and measurable operational savings while integrating into broader infection-control programs.

For a standard hospital patient room, ROZOR typically completes a full UV-C disinfection cycle in the order of ~7 minutes. That figure reflects an optimized clinical cycle for a typical room size and layout, and is deliberately short so facilities can maintain fast turnover. Actual cycle time will vary with room geometry, furniture and occlusions: ROZOR’s autonomy and mapping adapt the cycle to the room so the robot delivers the required dose where it’s needed.

There isn’t a single answer — frequency depends on clinical protocols, room classification and risk level: high-risk areas or rooms after aerosol-generating procedures typically need more frequent cycles than low-risk administrative spaces. ROZOR is designed to support protocol-based scheduling: the Fleet OS lets teams schedule runs, track coverage and review logs so frequency can be set and audited according to your infection-control policy. For best results, align ROZOR use with your hospital’s operational guidelines (the manufacturer and infection-control leadership should define frequency by room type and intended risk reduction).

ROZOR supports two complementary verification approaches:

In addition, ROZOR’s Fleet OS produces coverage maps, delivered-dose estimates and automatic cycle logs so teams can track performance over time and tie disinfection activity to outcomes. Those system reports make it easier to audit cycles and optimize protocols.

ROZOR is intended for high-priority clinical and support areas where reliable, repeatable disinfection and fast turnover are important. Typical use cases include:

These recommendations reflect typical clinical priorities; the robot’s mapping, sensor suite and learning models let ROZOR adapt to each room and prioritize high-touch surfaces for reliable, repeatable results. For final deployment plans, infection-control teams should classify rooms and set schedules and acceptance criteria accordingly.

ROZOR uses an energy-dense LiFePO₄ modular battery designed for fast top-ups: ~80% in ~90 minutes and a full charge in about 120–150 minutes (model-dependent). A full charge supports hours of operation, allowing one robot to disinfect several hundred — up to ~600–700 m² per charge in typical deployments, depending on cycle settings, room layout and pauses for occupied areas.

At minimum you need a power outlet/charging dock and local wireless connectivity (Wi-Fi/Bluetooth) for the tablet/app and updates; Wi-Fi is recommended for software/model updates and fleet coordination. For multi-robot sites, the ROZOR Fleet OS (cloud) is optional but strongly recommended for scheduling, telemetry and compliance reporting.

ROZOR requires low day-to-day maintenance: remote diagnostics and over-the-air updates handle most software work, while modular hardware and an authorized service network enable quick part swaps and repairs. The Fleet OS tracks lamp hours, battery health and component status to support planned, data-driven preventative maintenance.

Operators use a simple tablet/mobile app for local control, and ROZOR’s Fleet Management platform provides cloud dashboards, coverage heatmaps, cycle logs and analytics for single units or fleets; open APIs support integrations with hospital systems.

No — ROZOR is built as an AI-first, autonomous platform so it does not require a dedicated specialist. Any trained staff member (cleaning staff or clinical staff) can start and monitor cycles from the tablet / mobile app or receive completion notifications. The system’s autonomous control, simple UI and human-friendly design mean the robot works with minimal hands-on supervision.

ROZOR’s standard operator training is compact and practical: about 4 hours of theory and 8 hours of hands-on practice, which covers safe operation, basic troubleshooting and day-to-day workflows. This curriculum is intended so routine staff become confident operators quickly.

ROZOR aligns with recognized international standards: examples referenced in our materials include BSI 8628:2022(used for post-disinfection microbial assessment), CE safety compliance and quality management standards such as ISO 9001. These certifications and standards guide how we design, test and validate safety and performance.

ROZOR is shipped with a comprehensive manufacturer warranty that covers hardware and software maintenance during the warranty term (our product materials reference a three-year standard warranty for the disinfection product family). After the warranty expires, extended and paid maintenance plans are available through ROZOR’s authorized service network and support channels. ROZOR also offers certified spare parts and an RMA/repair process via authorized service centers.

Safety is engineered at multiple levels: ROZOR combines a human-aware safety stack (360° detection cameras, lidar/vision and emergency-stop hardware) with autonomy logic that pauses or disables UV-C whenever human presence or motion is detected. These hardware and software safeguards, plus local interlocks and operator controls, ensure the robot never exposes people to UV-C during operation.

environments. For deployment examples and a list of reference clients, see the ROZOR brochure and the Customers / Deployments pages in our resources (we also publish case studies and ROI results for selected site deployments).

That depends on your hospital’s size, bed count, room types and desired turnaround frequency. A site assessment (room classification, daily turnover targets and cycle profiles) is the right first step — ROZOR’s Deployment team can calculate coverage and propose a fleet plan tailored to your needs. This collaborative assessment gives the most accurate, cost-effective fleet recommendation.

Get concise, expert briefings on AI-driven robotics, pilot programs, safety best-practices and real ROI from ROZOR